🚀 Elevate Your Pneumatic Game!

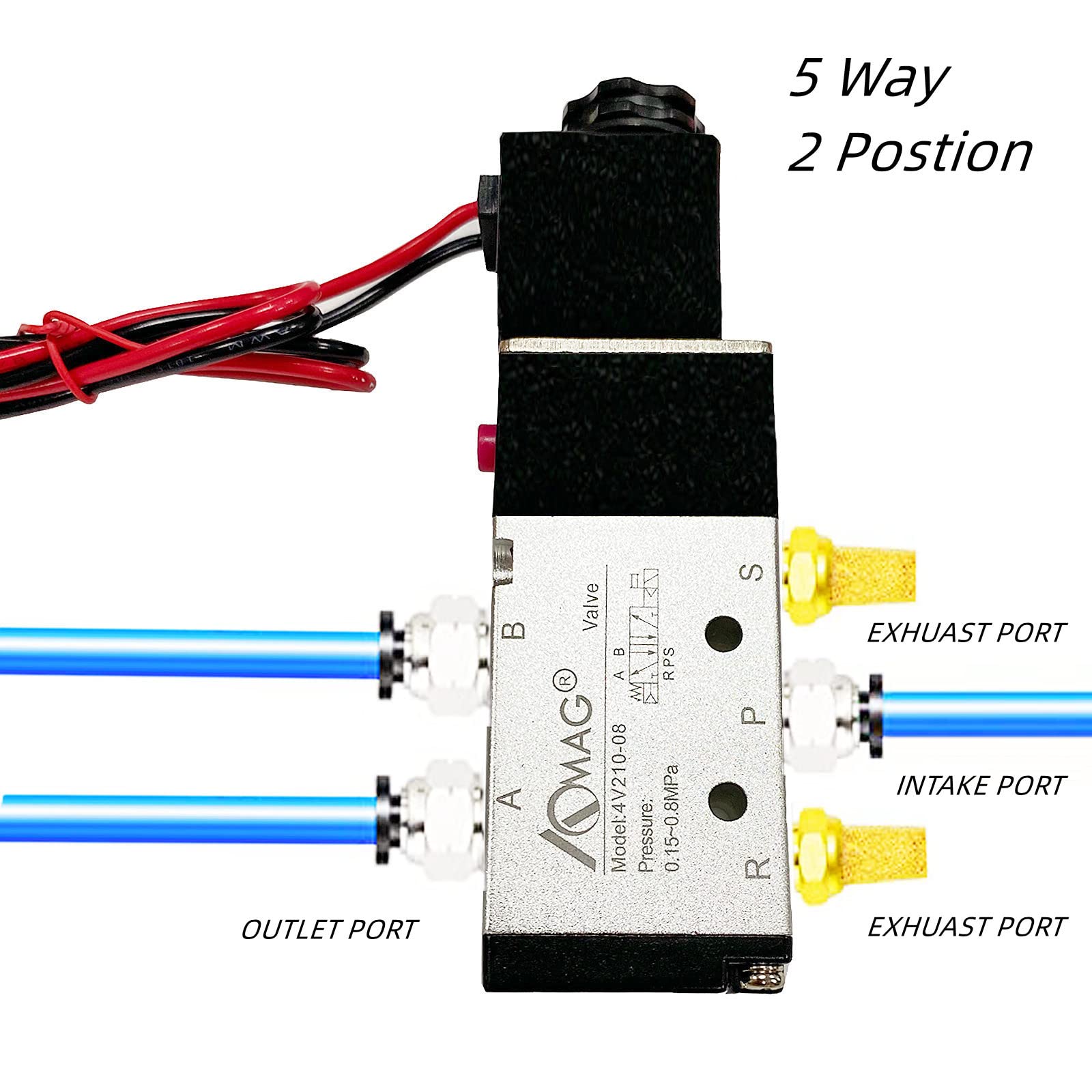

The AOMAG 1/4" PT Solenoid Valve 4V210-08 is a high-performance electric valve designed for efficient control of compressed air. With a durable aluminum alloy construction, it operates on DC 12V and features a compact design, making it ideal for various pneumatic applications. Its rapid response time and low power consumption ensure reliable performance, while the versatile connectivity options simplify installation.

| Manufacturer | AOMAG |

| Part Number | 4V210-08 JXS |

| Item Weight | 8.8 ounces |

| Package Dimensions | 4.84 x 2.83 x 0.98 inches |

| Country of Origin | China |

| Item model number | 4V210-08 JXS DC12V |

| Size | DC 12V |

| Material | Aluminum |

| Item Package Quantity | 1 |

| Batteries Included? | No |

| Batteries Required? | No |

V**A

Works great, connectors bad.

The solenoid value works great, but the connectors that come with is are no good. When you attach, they do not make an air tight seal. When I bought some separately, they work fine. The tubing is also hard to remove.

K**T

High-Quality Valve, BUT Instructions?

First, for the instructions/directions and an explanation of the working of this valve, go read what Jeff says (three-star review). Just to clarify, you MUST apply air pressure to this valve for it to operate the valve. It is a pilot valve controlled by the electric solenoid; however, air pressure moves the piston, not the solenoid. As Jeff says, applying 24v and blowing through it doesn’t work. Posigrade (four-star review) gives additional and helpful info.Now, for my review. PLEASE, PLEASE, include some instructions. So many people buy these without a working knowledge about pilot valves – they need instructions. Also, it’s nice to know which port is NO and which is NC. I, too, had to disassemble the valve to free up the stuck piston. That’s when I noticed the pilot valve.This is a solidly built valve with a really nice aluminum block body. Everything on the valve is quality – even the hard-plastic housing on the solenoid body. That body doesn’t need to be super tight; it only needs to be held in place. The sintered exhaust valves are very nice. There’s a stainless steel inlet screen to keep debris out of the valve.People who aren’t familiar with the type of quick connect fittings on this unit might find it difficult to remove the tubing. There is a special tool you can get that makes it much easier, or a pair of pliers works, too. Sometimes, pre-applied sealing compound works, sometimes it doesn’t. Teflon tape or paste is always easily applied. Also, if they are leaking, it might be because the tubing isn’t fully seated. If you have a leak, lubricate the ends of your tubing with silicone grease and push them back in. That might be all it takes.Amazon Vine sent this product to me for an honest unbiased review. Would I recommend it? Yes, this valve is a high-quality valve, although, the stuck piston and no directions/instructions lowers my review rating.

P**E

Surprising high quality, could benefit from instructions, arrived seized up.

The media could not be loaded. Update (8/3/23): It's been a long while, but I finally got the system that I got this for fully built and functional. It has not had any issues with seizing so far, and it is working as expected. I have uploaded a video of it functioning.Original review:I am an electrical engineer with extensive professional experience with pneumatic systems. As such I'm used to far more expensive valves, but I have to say these are impressive for this price point. I would not expect to see this level of quality until much higher up the scale.This valve works as expected, but as it is pilot-operated it can be confusing for people who aren't familiar with it. A small instruction sheet would have done wonders.Pilot-operated means that the solenoid opens a valve internally that in turn operates the main valve. In short, this valve will not function unless there is enough pressure in the system for it to operate the main valve! There is a MINIMUM pressure spec that must be met and maintained during operation for the valve to operate properly. This can make the valve appear that it's not working when it actually is working as intended.My valve arrived pretty seized up (as did another nearly identical valve I picked up), likely from sitting for long periods of time without being actuated. I only discovered this was the problem after opening it up and manually moving the valve piston. It is possible (likely) that a high enough pressure would have forced the valve to move, but I had been only trying low pressure before I realized what was going on. Keep that in mind for this valve, that sitting for long periods of time may require high pressure to get the valve moving again. So far this is the only major quality complaint I have, and something I can deal with for the price point.There is a red button on the side of the valve. There was no indication anywhere of what this button does. This button will actuate the valve while under pressure. It can be locked in place to keep the valve actuated by rotating it while pressed.As I got this particular valve as a component in a air-assist setup for my laser cutter. As it will run at high pressure and regularly, I don't expect it to sit long enough to seize back up. However if your application might be sitting long periods of time, and/or run at the lower pressures, do consider some kind of mitigation method like a regular test or regular actuation- even if it's just a manual test by pressing the red button while under pressure.

W**.

Good valve but instructions would be nice for us novices

I've worked with all sorts of tools and industrial type stuff, but never a pneumatic valve so the operation of this was a mystery to me. More information about this later, but here's what you need to know if you haven't used one of these before, you have to have the outlet ports hooked up to something for this to work.Here's what you need to know about the valve. It is a monolithic aluminum block that is well machined, with the solenoid valve attached to one end. The fittings are 1/8 PT (they don't appear to be tapered, but they might be NPT, however I am able to screw in a 1/8 PT fitting easily) type for the exhaust and 1/4" NPT for the inlet and two outlets. The outlet fittings are for 6mm tube, you can get 1/4 tube shoved into them if you try, but they're extremely hard to separate if you need to (don't ask me how I know!) The fittings have some sealer applied to the threads, but still leak quite a bit so you'll need to use some of the provided PTFE tape.Here's more info for the other noobs out there that are interested in this but are unsure how it works. I was under the impression that it was a direct mechanical process that moved the pneumatic cylinder rod to redirect the airflow. This is not the case, when the coil energizes/deenergizes a small valve is opened/closed in the black housing on the end of the unit that redirects a small amount of air from the inlet port that pushes a disk in that housing into the cylinder rod. The airflow is redirected by that action along with pressure/back pressure from the outlet ports. If you don't have anything hooked up to the outlet ports, the airflow is not going to be completely redirected. Once I finally figured this out, the valve worked great and redirected the airflow as expected. Lesson learned, I hope this helps others that are interested in using pneumatics to automate something.

W**H

Unclear how this works

There are no instructions with this unit. It arrived on time and undamaged. I thought that you apply an air source to the inlet, and it would come out of outlet A, then when you apply 12v DC to the unit, the solenoid energises and forces the air to come out of outlet B, but nothing happens. I can hear the solenoid energise, but air just keeps coming out of outlet A. Have I bought a dud, or is that not how it is supposed to work? Can't give more than 2 stars until I can make this work!

J**S

Gut

Gut

M**S

Ventil schaltet nicht bei bestromung!?

Ventil schaltet nicht wenn man 12 volt anlegt!?Woran könnte es liegen?

Trustpilot

3 weeks ago

2 weeks ago