Customer Services

Copyright © 2025 Desertcart Holdings Limited

🖤 Print Bold, Print Outdoors — The Ultimate Black ASA Filament for Pros Who Demand Durability

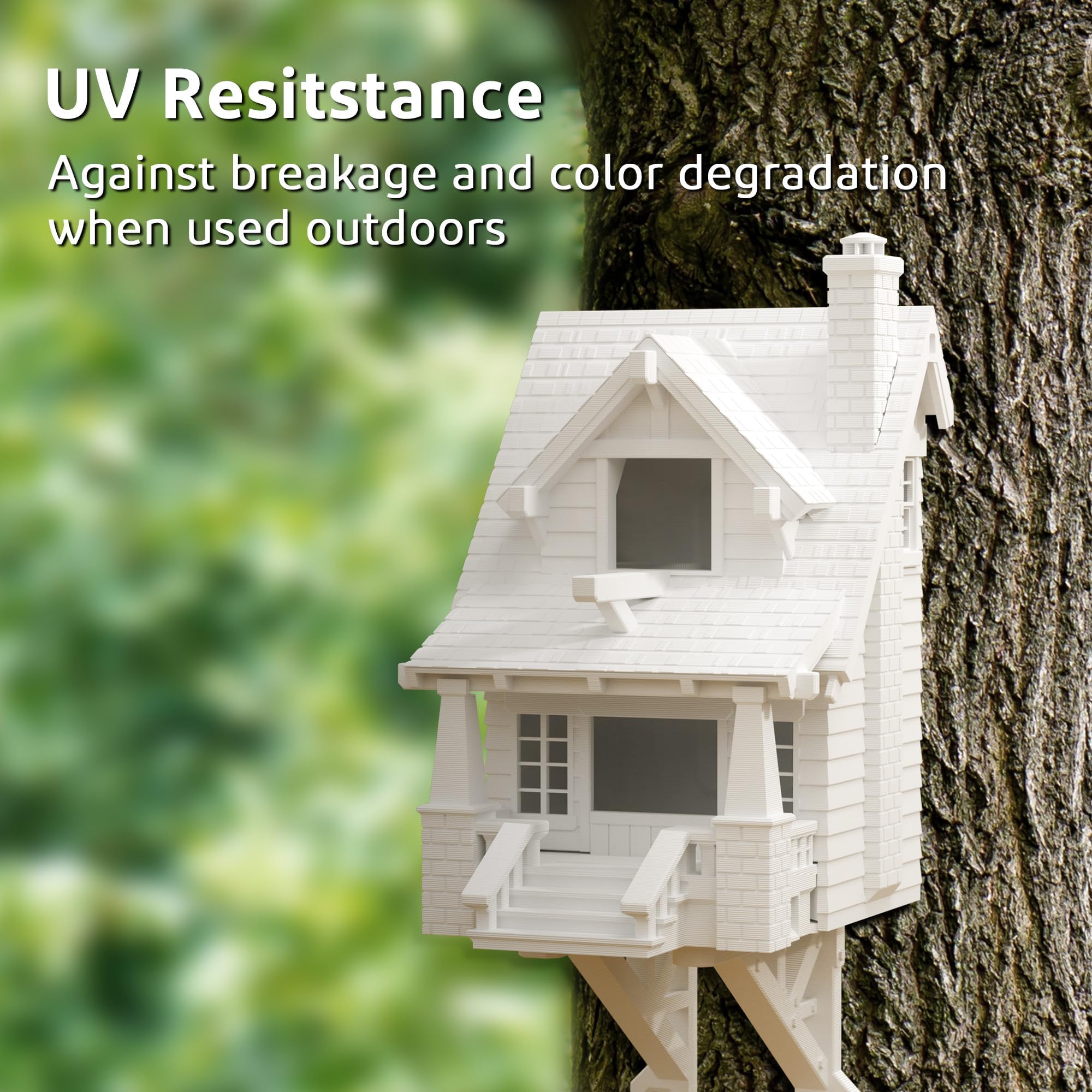

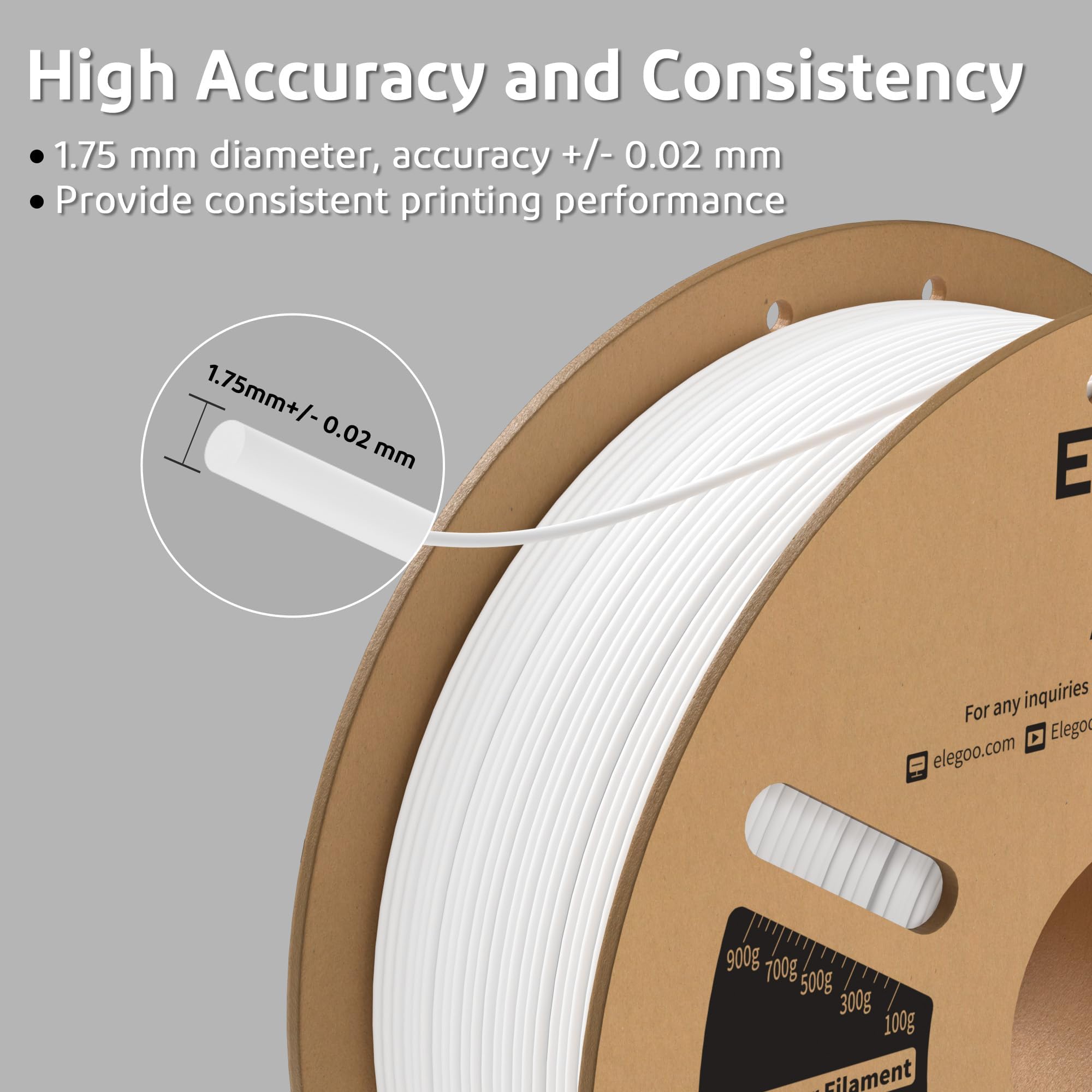

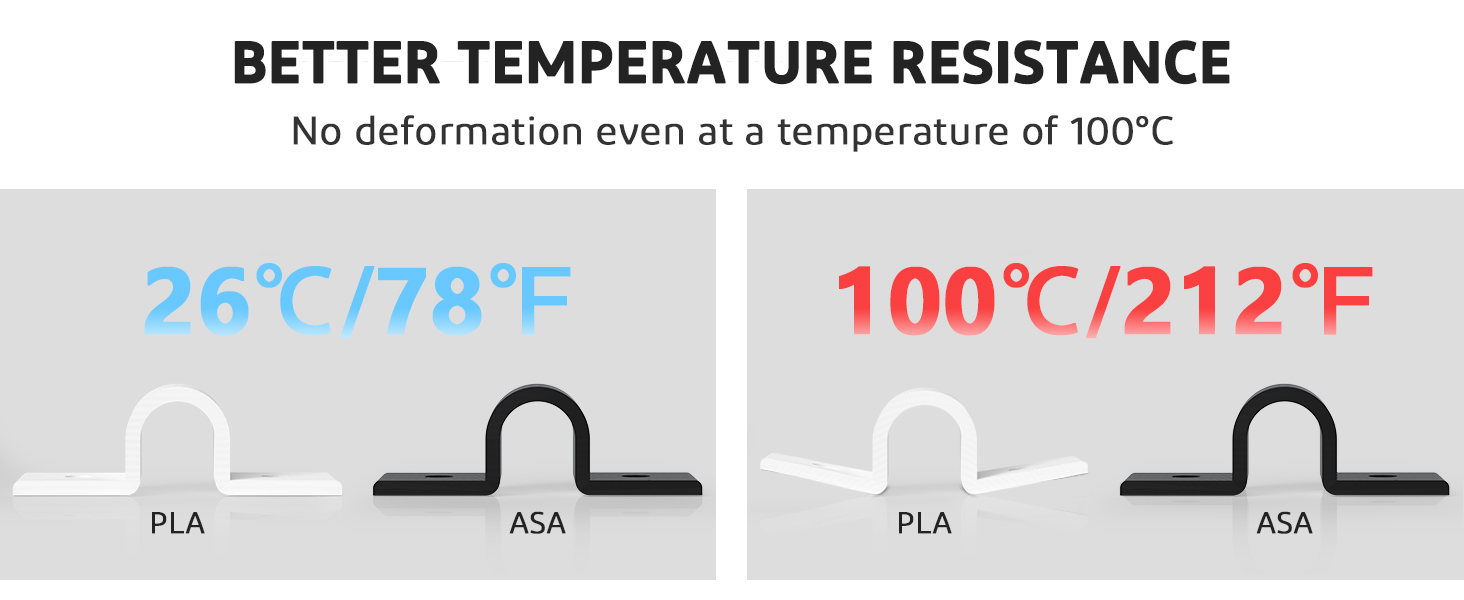

ELEGOO ASA Filament 1.75mm Black (2x1kg) is a UV and weather-resistant 3D printing material designed for outdoor and functional parts. It offers superior heat resistance compared to PLA and PETG, with a precise dimensional accuracy of +/-0.02mm. The filament is carefully wound on eco-friendly spools to prevent tangling and vacuum-sealed to eliminate moisture and dust, ensuring smooth, clog-free printing.

| Manufacturer | ELEGOO |

| Brand | ELEGOO |

| Item Weight | 4.4 pounds |

| Product Dimensions | 7.87 x 7.87 x 3.94 inches |

| Color | 2*1kg Black |

| Material Type | Acrylonitrile Styrene Acrylate |

| Number of Items | 2 |

| Size | ASA |

| Manufacturer Part Number | US-EL-3D-PAS03 |

A**N

Good but not for the faint of heart...

I'm beginning to really like Eleegoo's ASA filament. Well, mainly for it's low price. Just be aware the mysteriously low price makes sense when considering the number of issues with this filament.They have lots and lots of moisture and need to be heated at around 70c to 75c for at least 24 hours before using, and about 36 hours if you don't like to gamble. If I had to guess, I'd say they have at least a quarter-ounce of water per spool. If you want buttery-smooth prints, you gotta hit this thing hard with temperature and for long periods. And for that I made a custom heavy-duty filament dryer that can easily exceed 70C, so please bare in mind that anyone using standard filament dryers will be out of luck on this one.Aside from the moisture content, I want to emphasize that the next set of problems I encountered (listed below) are pretty rare and have not stopped me from buying the filament as it is way more cost-effective than Polymaker. Sufficed to say, at half the price, I'm willing to accept and overcome the challenges.The first problem I encountered with a couple of spools is that they were improperly wound. Somewhere right about the halfway mark, they started to bind and ruin prints. I corrected the problem, but it did add to the cost for the loss of material, time and also the slight damage caused to the PTFE tubing of the machine. But it happened about a year ago, so I guess it's pretty rare.The second problem which also is extremely rare is the filament in some spools can be very dirty/dusty in the inner sections of the rolls. Initially, they appeared clean but only on the outside. As the filament was consumed, somewhere deep inside the roll the dusty nozzle-clogging horror eventually revealed itself.In light of the problem, I use filament filter blocks to catch all that dust. I don't use the entire foam cartridge from the filter block. I cut the foam media in half to prevent binding resulting in smoother prints. I run my 3D printer almost daily and months will go by before I get a nozzle clog (I use 0.4mm nozzles).Clogs occur mostly when filaments have a lot of moisture and/or are not properly dusted using filament filter block before entering the hotend. The pockets of moisture within the filament somehow cause the plastic to expand and solidify inside the hotend under high temperature and pressure, producing carbon-rich particles that will not melt. Another reason for clogs are sticky filaments like TPU which leave a residue inside the hotend/nozzle that slowly 'cooks' and solidifies and it just builds-up over time. Last but not least, poorly-produced filaments sometimes contain particles and fibers that just can't make it out the nozzle.OTHER SOLUTIONS THAT WORKED FOR ME:- 260C at the hotend provides the best layer adhesion. But I had to run a slow fan directing air gently at the nozzle end and only at the nozzle end within a 40C minimum heated chamber to prevent warping. Why the crazy fan idea? It keeps the layers from deforming at 260C which is pretty high temp for ASA.-0.12mm first layer height provides best adhesion to PEI and the smoothest gap-free surface. If adhesion to the PEI bed fails, lower the nozzle offset by 0.02mm increments.-For better adhesion, spray 91%+ alcohol and quickly dry-off with paper towel to create a static charge on the PEI surface.-Every once in a while, use acetone to wipe the PEI bed which helps remove a thin, recurring, almost-invisible and sometimes oily layer of residue left behind by previous ASA/ABS prints.-0.2mm to 0.25mm layer height gives the best prints, at least for me. Due to the chalky viscosity of ASA filament, a 0.4mm nozzle doesn't seem to perform well below a 0.2mm layer height (with exception to the very first layer which prints fine at 0.12mm layer height).-The "Flow Ratio" in Orca Slicer filament settings worked best for my setup at 0.92 (I'm using an Orbiter 2.0 extruder).-A high-flow nozzle provides the best results, as ASA gets really chalky and generates too much back-pressure with regular nozzles.-Set the startup G-code to purge 2 to 5 grams of ASA on the start to prevent nozzle clogging. Why purge? It gets rid of the moisture-contaminated or degraded plastic inside the nozzle.-Retraction with a fast flowing hotend should be around 0.5mm.-To print reliably, I had to build my own extruder housing to run a generic, Bamboo Labs style hotend clone that unlike the authentic one allows me to use a hardened 3-hole high-flow nozzle. The Bamboo Labs hotend design is effective, as it allows the filament more time to melt before it exits the nozzle. Not to mention, the tiny heater core which is placed strategically right over the filament can make on-the-fly temperature corrections to prevent heat flashing which would otherwise lead to clogging. And it does so without generating back-pressure, reducing the need for so much retraction which is brilliant. But Bamboo Labs fails at not allowing the end-user to replace nozzles, namely with the high-flow variety. And that's why I prefer using clones on my custom made 3D printer running Klipper/RaspberryPI/OctopusPro board.ELEGOO VS POLYMAKERRegarding the quality formulation of the ASA plastic, it's actually very good, maybe even slightly better than Polymaker. It's easier to sand and smooths fairly well with acetone vapor and will print nicely if properly dried. Polymaker has better quality control but at double the cost.If you need to make low-cost, moderately good looking, functional, UV and weather-resistant mechanical parts, and you have the means, equipment and skills to mitigate all the problems, this filament will save you money. But if the price goes too high, which it might in the future, I will definitely stop buying it.It's also worth mentioning that the quality of the bulk packages is much worse. So I'd stick to ordering them in singles.Side note:Hopefully, this review made it past the super-sensitive, Amazon ministry of speech censor board. I'm just trying to help people get better results with 3D printing. I don't even use bad or racist words. But my last review was broadly deemed as "offensive, violent, racist or illegal" after posting a very happy and positive review for a shower fixture of all things. I went back and read the now censored material, and to this day, I'm left in awe scratching my head as why it's not acceptable. It's like walking on eggshells with these censors. They seem committed to building a boxed-in world where everything is perfectly bland, boring and unremarkable, free of sound ideas that might disturb groupthink, and free of 'wrong' exiting opinions or viewpoints that dare think outside the box. Ironically, all that power they think they have will soon be normalized to form a weapon of oppression which will later be utilized by some evil tyrant as a political hammer of sorts to crush and deprive us of everything we own and hold dear in this life.

M**T

Elegoo ASA – Redemption

Elegoo's Customer service reached out to me to try and make the situation right. They were outstanding and professional. They sent me a few new rolls and I've had no issues at all with these. I must have gotten a bad batch. These printed just as good as the first rolls as far as print quality and the spools were wound tighter and didn't pull the filament into the layer below it. After my experience with elegoo's customer service, I wouldn't hesitate to buy any of their products. They go out of their way to stand behind their stuff, I value that in a company. Thanks for your help Jenny and your concerns about my issues I had.I wanted to like Elegoo ASA—it’s affordable, prints well, and has solid layer adhesion. The quality of the filament itself is great, and when it feeds correctly, the prints come out strong and smooth.But there’s a major issue: the spool winding is terrible. The filament is often tangled or loosely wound, which leads to binding and knots on the roll. This causes extruder jams and failed prints, sometimes hours into a job. It’s incredibly frustrating to babysit prints just to make sure the filament doesn’t snag.At this price point, it had the potential to be a go-to ASA filament, but the spool winding issues are a deal-breaker. Until Elegoo fixes this, I can’t recommend it unless you’re willing to monitor your printer constantly.

N**N

New Experience

I have been in the 3D printing world for about 13 years and this is my first trial of ASA.I needed a filament for an odd project that would give good printing results, heat resistance and good strength, like ABS without the downside and PC without some of it's querks. After researching materials ASA seemed to fill the bill.I have had good results with Elegoo Filaments in other projects and they tend to be very cost competitive. The Elegoo filaments are also readily availabe. The only issue I have encountered with Elegoo Filaments having use PLA, PETG, ABS, PC and now ASA is a rare spool that is cross wound requiring respooling to save the spool.The Elegoo ASA gave VERY good results. My slicer did not have recommended parameters for ASA. Looking into suggestions, the recommended guidelines looked similar to PC (Polycarbonate) filament, I used these.First results were excellent. Very good bed adhesion, no stringing, very little shrinkage, no layer separation, good bridging and high definition.This particular spool was black and the first prints were perfect.

J**N

Works well

I've used several rolls of this filament and have had success every time. Parts come out clean, good layer adhesion, little to no warping. If you need some good quality ASA at a great price this is it. I've used this on my Elegoo and Bambu printers.

N**.

Poor Layer Adhesion and Soaked with Moisture

Wanted to like this filament, but after printing about 20kgs of this stuff, i just cannot recommend it. Ive printed ~400kgs of Polymaker ASA and have never had the kinds of issues ive had with this filament.I print large parts, typical one panel takes 1 kgs, and a whole product takes 8kgs.This filament is SOAKED with water, when I first started using it, i could watch the steam constantly fuming from the nozzle, and of course the accompanying imperfections and blobs accustom with wet filament. Having to dry EVERY roll is a huge pain in the buttocks.The layer adhesion is really poor for printing panels. Im using 260+ temps with a CHT/High Flow nozzle, zero cooling, typical ASA setup with heated enclosure. It adheres fine to my garolite build surface, but will split at the layers. Im sure printing with hotter temps helps, but this is really concerning.If you're making products for others and have a certain quality of product they expect, I cannot recommend this ASA, at all.

Trustpilot

1 month ago

1 month ago