Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🖨️ Flex your creativity with precision and strength!

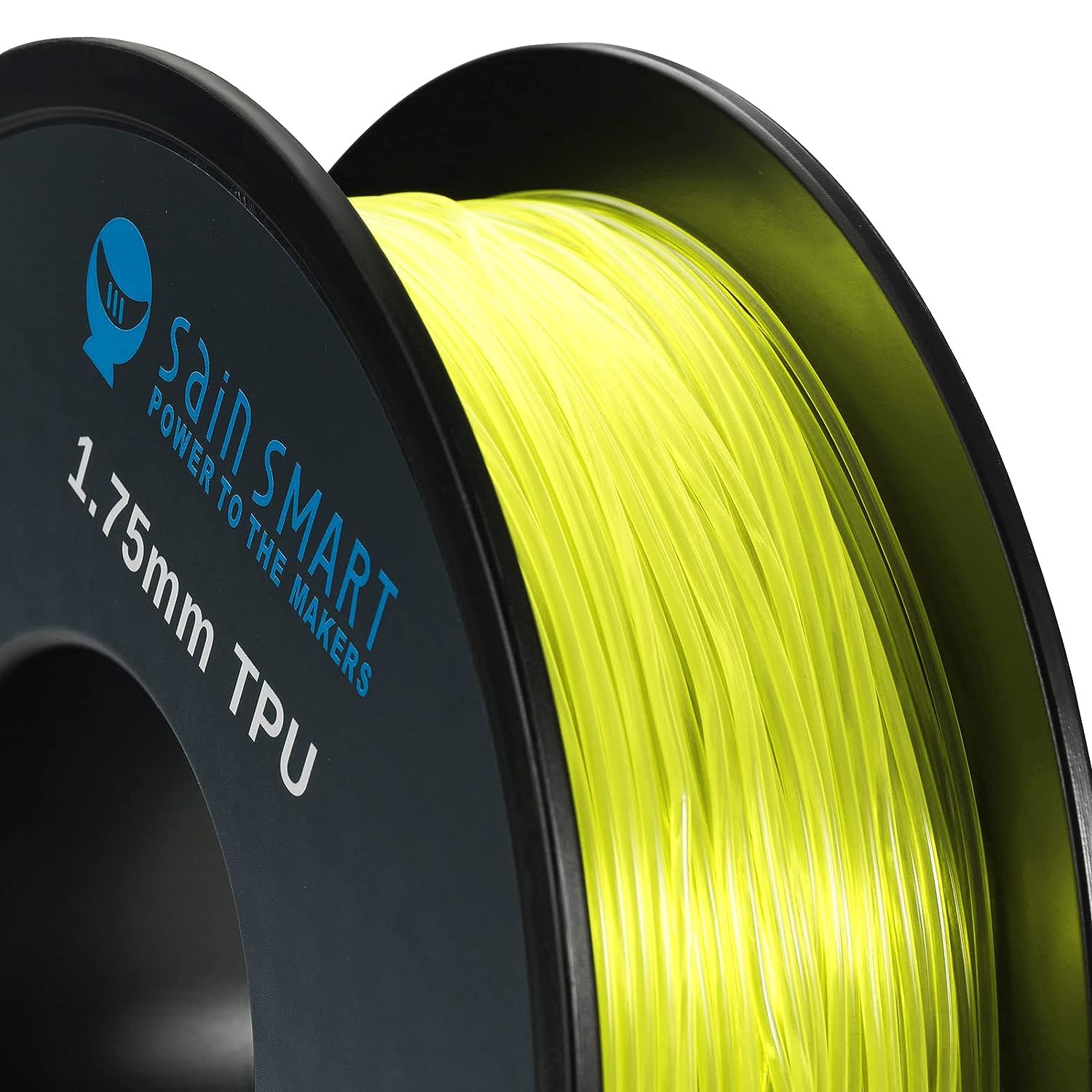

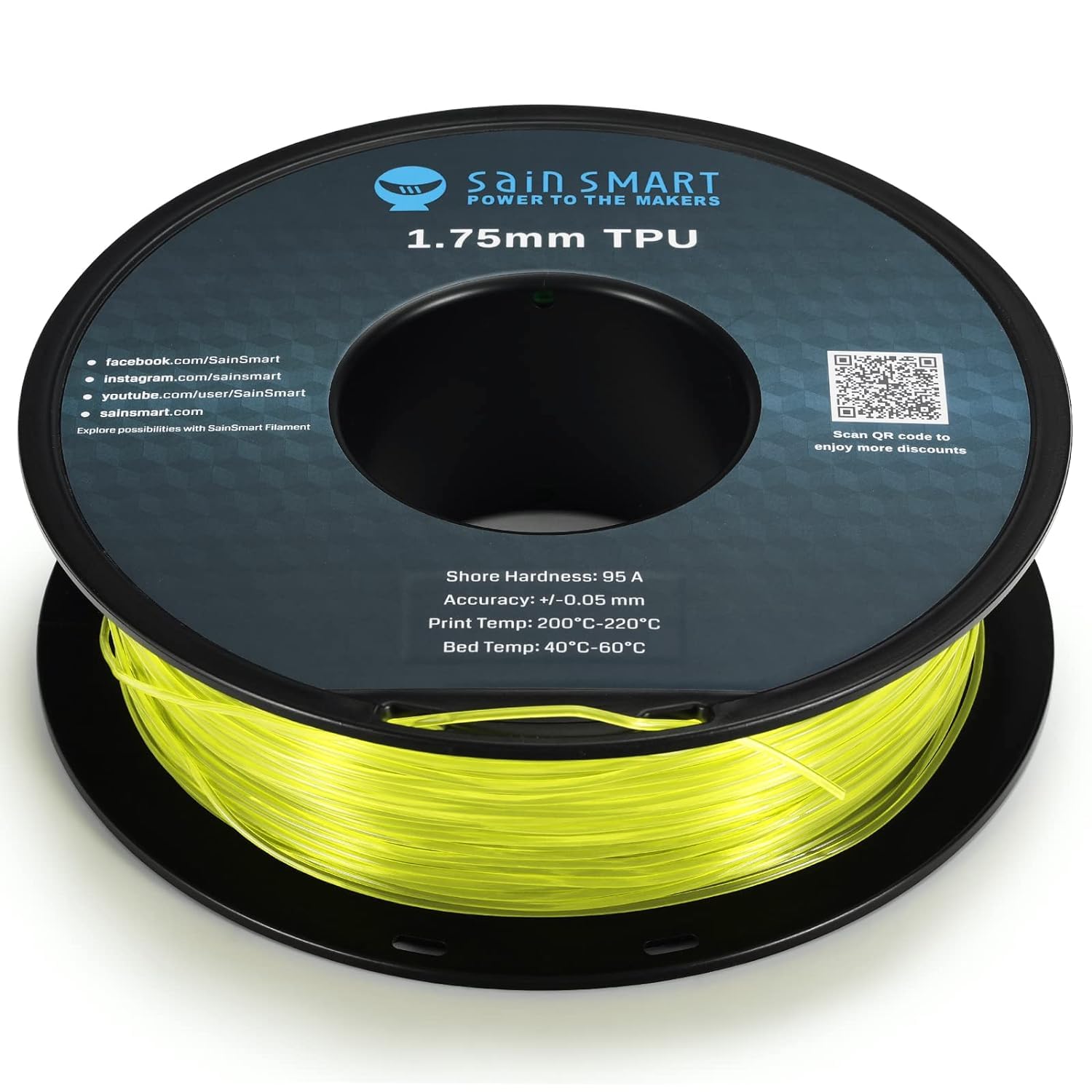

SainSmart's 101-90-160 Yellow TPU filament offers 0.8 kg of high-quality, flexible thermoplastic polyurethane with a precise 1.75 mm diameter and ±0.05 mm dimensional accuracy. Compatible with all major FDM 3D printers, it ensures strong, flexible prints with excellent bed adhesion and minimal warping—perfect for professional prototyping and creative projects alike.

C**I

Five Stars

If you have a mk3, copy the following into a text file name it 'sainsmart.ini' and then load it into slic3r. It will me the difference between ugly and messed up prints to beautiful outputbed_temperature = 70bridge_fan_speed = 100cooling = 1disable_fan_first_layers = 1extrusion_multiplier = 1.03fan_always_on = 1fan_below_layer_time = 100filament_colour = #000000filament_diameter = 1.75filament_max_volumetric_speed = 0filament_notes = "SainSmart 1.75mm Flexible TPU 3D Printers Filament - 1kg Spool (2.2 lbs), Black"filament_settings_id =first_layer_bed_temperature = 70first_layer_temperature = 225max_fan_speed = 100min_fan_speed = 85min_print_speed = 15slowdown_below_layer_time = 25temperature = 220I found these settings on Prusa's forum but wanted to pass along.

S**.

Excellent value in a TPU filament

Just received my first reel of this material and I must say that I'm quite pleased. I print a lot of flexible filament (Ninjaflex and Filaflex) and this material compares favorably.Unlike the Sainsmart ABS, this filament comes on a plastic reel with a "standard" size bore, so it will fit on most printers. I checked over the first few meters of filament and the diameter was consistent and to spec. As noted in the specifications, this material is 95A durometer, so it is "stiffer" and less elastic than Ninjaflex and Filaflex. That means that it is easier to extrude, and generally speaking is less "stringy", but it won't be as "Gummy Bear" flexible as the 85A filament from the competitors.You will still need an extruder that is able to handle flexible filament (good guidance from the drive "wheel/gear" to the top of the thermal tube). This material might work better in a Bowden setup than the 85A stuff... but I still think that direct drive is the way to go with most all TPU's.I have printed it at 230C, 235C and 240C on a Makerbot R2X. I get the best overall clarity @ 240C, but you start to lose layer definition. 230C still gives extremely good layer-to-layer fusing and adhesion.

K**R

Definite Quality Control Problems, but Sainsmart trying to make it right.

Update 1: Sainsmart contacted me and offered to replace the bad rolls and give the filament another shot. I gave them my address, etc., but a month later and no filament ever showed up, so I'm keeping this review at 1 star. If the new filament ever shows up and it works out, I'll update this review.Update 2: Sainsmart shipped the filament to the wrong address, even after I sent the correct address. I finally received it two months later.Update 3: I got a chance to use the TPU, and unfortunately it still had the same exact quality problems I experienced previously. Many hours of wasted prints. In addition, the TPU was full of moisture fresh from the package and had to be dried in my food dehydrator overnight before it would print properly.Update 4: Sainsmart again sent me new replacements (again to the wrong address). This time from a different factory and on different rolls. It looks suspiciously like the same rolls used by Yoyi. I have high hopes for this one. Raising my review by 2 stars just because Sainsmart is obviously trying to make it right.When it works, it works fine, but there are definitely some quality control problems. See attached picture. This plugged up my extruder and made a 23 hour print fail. (not happy!). The filament diameter goes up from 1.69mm on average all the way up to 2.5mm in spots. I've seen it go down to 1.6mm in diameter.Unfortunately, I purchased 5 rolls of this for a big print job. There is cheaper TPU filament that I had zero issues with (Yoyi I believe).The good: Prints very nicely when you get a roll that has a long enough portion where the diameter is consistent. I even got it to do some pretty decent bridging.The Bad:Diameter is all over the place. No consistency.Spool was wound poorly, so when you get to the end, the TPU is very wrinkled. OK for a direct extruder, but death to a Bowden extruder.Print settings:Glass bed with PVA glue coating at 70C gave perfect adhesion.First layer nozzle at 230, and then all other layers nozzle at 205C. (230C is the key to good bed adhesion, and 205C almost eliminates stringing)Fan off first layer, 100% for subsequent layers.Excellent layer adhesion.25mm/s print speed with direct drive extruder. 20mm/s print speed with a Bowden extruder.Sainsmart would have a good product if only they could get it to be a consistent diameter. This roll is definitely going back for a refund. The others I'm forced to use because I need them right now. I've already had several failures from the other rolls, but when you're in the middle of a big print job, you do what you have to do.

R**F

Loved This Filament!!!

Just Received this filament. This is my first time printing a flex filament. I am very happy with it. Printed great. No jams and it stayed stuck to the bed. When the print cooled it popped right off. I will be buying more this. :)Printer: Flashforge Creator Pro(Print time: 2 Hours)Glass bed and UHU glueExtruder Temp: 220cBed Temp: 70Slicer: Simplfy 3dSlicer Settings:Default Printing Speed: 30.0 mm/sFirst Layer Height: 95%First Layer Width: 120%First Layer Speed: 50%Outline Underspeed: 30%Solid Infill Underspeed: 35%

M**S

Fantastic material once you work out the settings

You have to hit the 'sweet spot' but once you find it, it prints well every time.In comparison to rigid ink TPU I'd say that rigid ink TPU was easier to print with, but it was completely impossible to remove the print without damaging it, this stuff is easy to remove and easy to separate from support material. The rigid ink TPU printed more successful overhangs, but SainSmart works well with support material so that balances out. The main advantage of course is this is available in a range of colours.I've printed a toy tractor tyre and a synchronous belt (seen in picture below), I found the right settings through trial and error.I'm using a FlashForge Creator Pro with Simplify3D software and the following settings:1500mm/min printing speed with 50%, 80%, 80% for outline, solid and support respectively.210 degrees C nozzle temp and 70 degrees C buildplate0.1 layer height and 6 layers top/bottom and 4 outline.I always use a raft and it separates well from it.The real interesting setting I changed was I set the extrusion width to 0.37mm and extrusion multiplier to 1.10 (i.e. I wanted it to squeeze more material out into a smaller space as I found the extrusion layers were very visible and resulted in poor layer adhesion within each layer).I

S**R

An excellent flexible filament

An excellent, flexible filament that produces good results.The finished product is very flexible and will stretch or bend a long way before coming apart.Probably best printed with an extruder mounted to the head, but I printed using a bowden system.Retract doesn't work because of the flexible nature of the filament.Make sure the distance between your extruder gear and nozzle is as small as possible otherwise it will buckle up.Top layers printed on a 10% fill struggled to bridge the gap and took several passes before covering.Perhaps a higher percentage, e.g. > 50% fill should be used?

M**A

Absolutely perfect results first time - it's a lovely material mechanically ...

Printed at 210 on a cold bed with a 0.5mm nozzle. Absolutely perfect results first time - it's a lovely material mechanically and visually - not really squishy but flexible enough for rubber washers and gaskets - I've printed isolating bushes for my CoreXY motors and it is perfect. I print with all manner or materials, and this is now my go-to flexible filament.

J**E

Great filament. misleading advertisement.

This is the first semi-flexible filament I have printed. I printed a new extruder first to make sure the filament path was well constrained so that this filament wouldn't kink between the feed gear and the PTFE throat. I have had no problems printing this filament using my upgraded MK10 extruder. I have tried 20-40mm/S and print quality doesn't degrade at this speed. I probably wont try print this any faster, I feel that would be pushing my luck.I am quite disappointed to knock a star off such a good filament. It is a pity the seller sells this as a "approximately 1KG roll". I suppose that is true, 800g is "approximately 1KG". But it clearly states on the roll that it is 800 grams of TPU. Why advertise otherwise?

S**M

Lovely to print (advice below)

Love printing with this stuff! Wish I could afford to get more quickly.You'll need to get your nozzle more hot than usual, I run at 240°C as opposed to my usual 200°C. Once you've reached temperature it prints beautifully on a cold bed. Also, depending on layer size play around with the temperature slightly. When it runs a bit too hot it comes out sort of matte with a silver sheen. When it comes out just right it's this rich, shiny black.

Trustpilot

1 month ago

2 months ago