Customer Services

Copyright © 2025 Desertcart Holdings Limited

🛠️ Nail every joint like a pro—because your craft deserves precision and style.

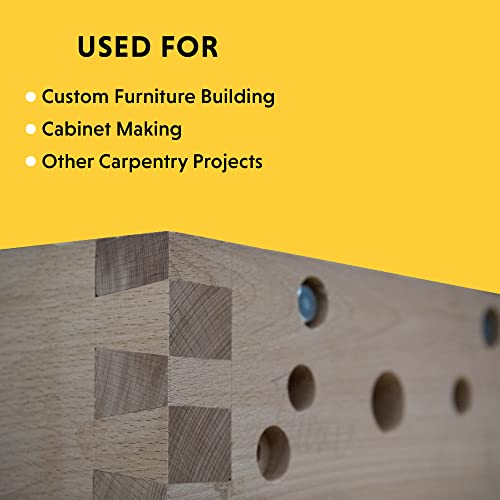

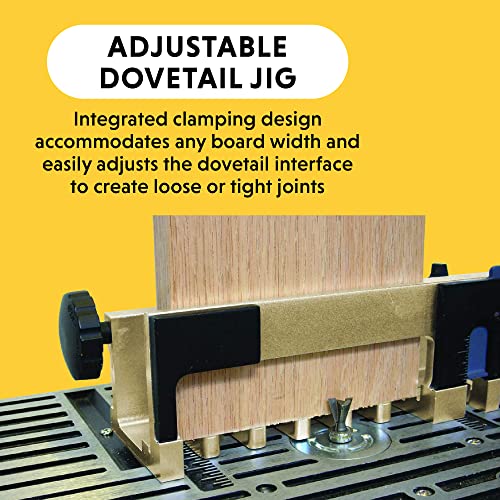

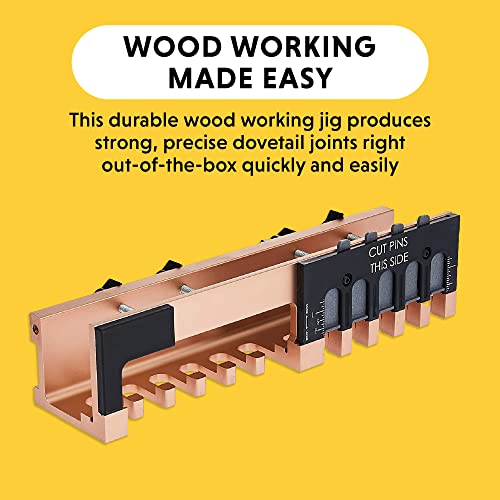

The General Tools 12-inch Dovetail Jig is a precision-engineered aluminum tool designed for creating strong, professional dovetail joints with ease. Featuring an adjustable clamping system that fits any board width and including a 14-degree, ½-inch dovetail router bit, it supports a variety of joint types from half-blind to through joints. Lightweight and portable, this jig is perfect for both novice woodworkers and seasoned professionals aiming for flawless joinery in indoor and outdoor projects.

| ASIN | B007E9IMP0 |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #44,726 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #102 in Power Tool Accessory Jigs |

| Color | Gold |

| Customer Reviews | 4.1 4.1 out of 5 stars (1,713) |

| Date First Available | January 7, 2011 |

| Included Components | (1) 861 Dovetail Jig & (1) 14-degree, 1/2 -inch dovetail router bit for use with hand table or table router |

| Is Discontinued By Manufacturer | No |

| Item Package Quantity | 1 |

| Item Weight | 2.94 pounds |

| Item model number | 861 |

| Manufacturer | General Tools |

| Material | Aluminum |

| Number Of Pieces | 1 |

| Part Number | 861 |

| Power Source | Hand Powered |

| Product Dimensions | 12 x 3 x 3 inches |

| Size | Pack of 1 |

| Style | Modern |

| Warranty Description | Warranty |

C**R

Works well, with a small amount of practice on scrap. The provided bit isn't for very hard wood.

After 2-3 practices on cut off stock, It works well. Like any other tool, the more you use it, the better you get. When using harder stock than Walnut, like Purple Heart, when cutting pins be sure to listen to the router. That way you can hear when the bearing touches the plastic stop, as it's harder to "feel" when using very hard wood. I used a router table, which I'm sure produces better results. Very hard wood, like Wenge, and Purpleheart, is already prone to router and planer tear out. These woods are much harder than domestic hardwoods. The second photo shows Purpleheart and Wenge. I had some minor tear out on one of the Purpleheart tails. That was not the fault of the jig, but the nature of the type wood. A backer board would help. Domestic hardwoods work no problem. Through joints work ok, but don't come out perfect. Ensure the Pins board is cut using the EXACT thickness of the Tails board, like I didn't do. I finally got around to trying Edge-to Edge dovetails. They works well too.. The example is two edge-to-edge dovetails per box side (eight total), mitered, or beveled. It is the Quilted Maple with Leopard wood corners. I did find an issue with the provided bit. On harder wood, harder than Walnut like Purpleheart, or Bloodwood, the bit dulls even more rapidly. But more seriously, on harder wood, it can come loose in the collet. Initially, I thought it was my OEM collet. I bought a Whiteside collet, same thing. Later, I noticed the exposed shank, below the bearings, was shorter than my other ¼" shank bits. Anyway, I burned up the provided bit on the wine rack. Bottom line, the included bit sucks. I now use an Amana 14 degree ½" X ½" dovetail bit, and it works fine. But I guess that helps keep the package price down. I still love the jig, for the price. Edit: A backer board is a must for me now. I like to run a marking gauge lightly the height of tails of the tails on both sides prior to cut. That's just me.

R**Y

best dovetail joints I ever made

Great jig...after you dial it in with adjustments, nice, tight dovetail joints. I would definitly recommend this. Easy to learn.

A**R

Worked well with some reservations.

I bought this after searching for a mini dovetail jig. I was looking for a jig to cut small dovetails. This is more of a small jig to cut larger dovetails. However, although the instructions say that it works for material thickness of 1/2 inch and greater, I successfully cut through dovetails in material slightly less than 3/8 inch thick. I am done with that part of my project and may never have use for it again. If I were to use it a lot I would be concerned as the plastic pin guides are already showing some wear where the guide bearing rides against them. Speaking of guide bearing - make sure the set screw in the locking collar is good and tight. I used it with a small Menards trim router that I have - the trim router was a good match to this jig. The box with the included foam made it easy to store everything together when I put it away until who knows when.

D**E

stroke victim

I have a Kreg router table with a Bosch 1617 router, and a Jess em Lift. Feud Bits and now my set up is complete with the General Dovetail and box joint jig. Works as advertised, Price is great and you tube videos also. A must have in the shop.

S**Y

Good but bent

I like it but one end is bent slightly, and router hangs up there. Can I get a replacement for it or just bend it myself?

W**T

Joints Don't Fit

Before I purchased this product I read many of the reviews. Some spoke of the joints not fitting well. One user said he chalked that up to user error. While that may be true in some cases, I don't believe it was in mine. I spent hours making joint after joint on 3/4 inch board and none of them worked. I set the tails to 1/2 inch, which I think is reasonable. I pounded and pounded with a rubber mallet, but the tails were just too big for the pins every time. I tried it with slightly smaller tails. Still too big. I finally did get one to work on a board I had planed down to 3/8 of an inch with the tails at 1/4 inch. But that joint was so loose it fell apart if you didn't hold it together. I'm disappointed because out of the box, the jig appears to be well made. This 861 version has some significant improvements over the 860 and I was excited to see what I could do with it. After repeatedly reading the instructions from cover to cover AND watching a handful of Youtube videos dealing with the 860 version, I could not for the life of me see where I was going wrong. The jig is not a complicated thing. It does not require a high level of knowledge to figure out or use. But I just couldn't get it to work satisfactorily. I tried it on my router table and also by clamping it to a work bench. Same results. Part of me wonders if I just got a defective one. The Youtube videos made it look like it would work every time. But I'm not going to chance exchanging it for another one. It's getting returned and I'll look at something else.

M**L

Handy tool

This is a handy tool and great for first time users. The instructions are very helpful, tool comes with a dovetail bit as well, so no need to purchase any other items suggested when purchasing the tool. The alignment tools provided with this tool take some patience to set up, but you need to take your time with this detailed joint if you want a tight joint. I did experiment on the joint on scrap pieces of wood as suggested to make sure I got the desired tightness and to learn to work with each of the alignment components. I was building shelves (12-inch wide boards), so I wish I had purchased a tool that could handle the full board width. The slot centering tool provided with this tool is very handy and works well, but the limited width required I reset the tool multiple times for each joint. Overall, I am very pleased with this purchase - it is good for joint widths less than 4-inches. If I was to make more shelves, I would invest in the wider unit.

S**O

Das Teil kommt in einer ordentlichen Verpackung und man sieht sofort, dass es für den amerikanischen Markt gemacht ist. Offenbar hat man im Laufe der Zeit auch immer wieder Kleinigkeiten verbessert, z.B. die Befestigungen für das Werkstück (sieht man in alten Videos). Es ist vollständig aus Metall (Aluminium) und ordentlich verarbeitet. Montiert werden muss nix. Man kann lediglich die beiden Griffe für die Arbeit am Frästisch anschrauben und muss sie wieder abschrauben, wenn man mit dem Fräskorb arbeitet. Bzgl. US-Produkt: Die Anleitung und das Video sind natürlich auf Englisch. Alle Angaben sind in Zoll (2,54 cm). Der beiliegende Fräskopf ist auch mit einem 1/4" (Zoll) Schaft - den legt man am besten gleich zur Seite, weil der sowieso nicht in eine Standard-Fräse für den deutschen Markt passt, und kauft einen mit 8 mm Schaft in besserer Qualität (gibt’s hier z.B. von ENT 16200). Man sollte sich schon mal einen Tag Zeit und diverse Probebrettchen nehmen, zusätzlich die Anleitung und das Video schauen, bevor man richtig loslegen kann. Es ist wirklich nicht schwer und macht richtig Spaß, wenn man den Dreh raus hat. Schwalbenschwänze erklärt das Video sehr gut. Das beschreibe ich hier nicht extra, werden aber ordentlich (s. 6. Foto) und halten auch. Bei den Zinkenfräsen braucht man wieder einen mit Kugellager am Schaft (Bündigfräser). Der Durchmesser muss genau 12,7 mm sein (1/2"), sonst fräst man zu viel oder zu wenig und die Zinken passen nicht. Er muss um die Länge der Werkstückdicke + Dicke der Zinkenschablone (ca. 7mm) + Zugabe (ca. 0,5mm) herausragen UND (das gilt auch für Schwalbenschwänze) dann immer noch mit dem einen Kugellager an der Zinkenschablone anliegen. Denn - aufpassen: Die Zinkenschablone hat nach hinten eine geringere Dicke (S. 3. Foto). Wenn man die Frästiefe nicht richtig einstellt, schrammt man gleich mit dem Fräserschaft an der Schablone entlang oder man rutscht ab! Das ist bei den Schwalbenschwänzen noch relativ einfach einzustellen, bei Zinken aber schon tricky, weil der Fräser dann nicht mehr lang genug ist. Ich habe mir so geholfen, dass ich das Werkstück weiter nach hinten und nach oben versetzt habe (s. 4. Foto) mit einem 12 mm Brett als Zwischenstück geht’s (es entsteht eine minimale Lücke, vermutlich 0,7 mm, ist aber nicht schlimm). Und dann bekommt man perfekte Zinken (s. 1. und 2. Foto mit Überstand und plan geschliffen - da war ich etwas hastig, ist ja nur zur Probe). Kurze Anleitung fürs Einstellen der Zinken: Erstes Brett einspannen und den Fräser an der linken Seite der Zinkenschablone entlang führen. Nur links! Wir wollen genau 12,7 mm oder 1/2" heraus fräsen. Zweites Brett dann an der rechten Seite der Zinkenschablone entlangführen. Markierung: Hat man das erste Brett gefräst, legt man beide bündig übereinander und zeichnet die Lücken vom ersten auf das zweite Brett. Dann markiere ich immer noch die Teile, die ich wegfräsen will (weil ich sonst unter Garantie die falschen Teile weg fräse) und stelle den rechten Rand der Markierung so ein, dass er bündig mit der Zinkenschablone verläuft (Ablauf, s. 5. Foto). Werkstück festspannen und wie oben erklärt an der rechten Seite entlang fräsen. Schaut man sich die Markierungen an, sieht das unlogisch aus, als ob zu wenig weggefräst wird - aber es funktioniert! Mit Fräskorb oder am Frästisch arbeiten? Ist eine Philosophie-Frage. Wenn man sich sicher genug fühlt ist die Frästisch-Methode sehr komfortabel, denn das Festspannen der Schablone wird schnell lästig. Beim Frästisch spannt man das Werkstück ein, dreht das Ganze um und legt los (Links und rechts auf der Unterseite markieren, sonst kommt man durcheinander). Außerdem fliegen die Späne nach hinten weg und können abgesaugt werden. Mit Fräskorb fliegen die einem immer ins Gesicht. Zinken und Schwalbenschwänze sitzen schon ohne Verkleben bombenfest und ich brauche einen (Schon-)Hammer, um die wieder auseinander zu bekommen. Also klare Kaufempfehlung und trotz der englischen Anleitung 5 Sterne, weil es mir gefällt, dass das Produkt komplett aus Metall gefertigt ist und sich mit dieser Farbe schon fast als Deko-Objekt anbietet!

A**O

Boa ferramenta, muito funcional, e excelente acabamento!!

R**I

I have had a few different dovetail jigs, but this is the easiest to use and most accurate. I could recommend it to anyone from hobbiest to journeyman.

C**N

Great tool! Perfect for dove tails and half blind dove tails.

C**O

, me gusto

Trustpilot

2 weeks ago

2 weeks ago