Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🔧 Screw it, get organized!

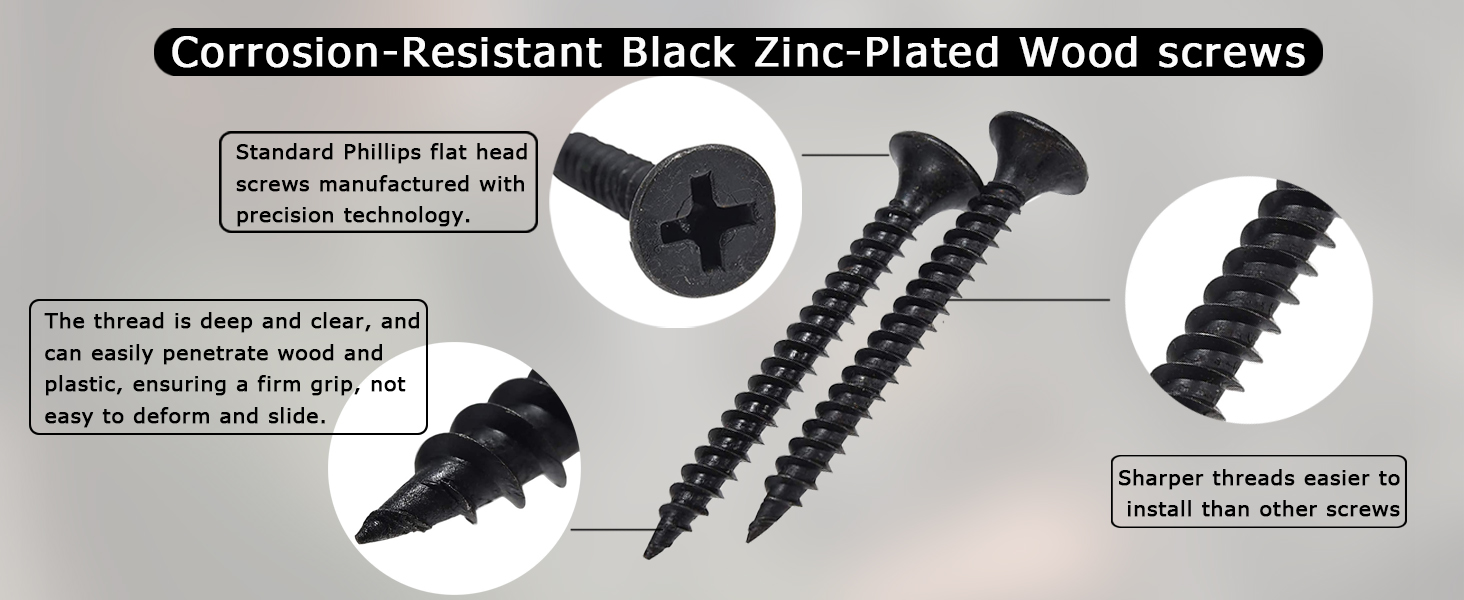

The M3 Flat Head Wood Screws Assortment Fasteners Kit includes 420 pieces of high-quality carbon steel screws, designed for durability and precision. This comprehensive kit features 8 different sizes of self-tapping screws and M6 screw anchors, all neatly organized in a sturdy storage box, making it ideal for a wide range of applications from DIY projects to professional maintenance.

J**.

Come on people!!!

These screws aren’t for building a house! They are small and do the job they are meant to. Look at the sizes and not the pictures before buying. They also do not use a #2 screw driver.I personally use them while building acrylic cases for PCB boards. After drilling out a pilot hole they screw in just fine.If you put the driver in squarely and have a pilot hole then they will work just fine for any LITTLE jobs you might have. I would buy again!

R**Y

Great product

Work very well. Just what I needed will buy again.

J**L

Good 👍🏼

Good

T**L

Super Handy!

I’ve had a couple of these screws break on me but I wasn’t using them for their intended purpose really. When they broke I was drilling into brick mortar so I’m not at all surprised they snapped. These are definitely not masonry screws so the breakage was 100% my fault.I’ve been really surprised at just how much I’ve used these around the house. I’ve used them for all kinds of things. So much so that I’m buying my second box today.People should keep in mind that these are small screws - 3 mm in diameter so a resistant surface plus pressure on the screw will break some. It’s just physics.

M**R

Tiny

These work fine, but they are TINY! I guess I should’ve read the description more carefully.

S**N

These screws are bad :(

Had to throw these away after trying a few times, the metal is too weak to drive them into wood and just will strip the screw right away before it drives it into the wood.

R**O

Very good

Very good

L**D

Pre-drill & prep holes, use a light hand, these are near perfect

Purchased both stainless & black versions of these M3 screws and found them both to be excellent. Intended purpose, to attach hardwood trim to cabinetry with hardwood facing (all cherry), in some areas mounting the trim onto the plywood used in the cabinet boxes. Intention was to have no screws visible so screws were inserted from 'back" so either through the cabinet facings or the plywood.Cut to the chase, what worked really well for me...TL:DRDrill full 3/32" pilot holes, then 1/8"clearance the holes in "through" material, and 1/4" countersink in hard materials. While "full-size" 18V impact wrench or screwdriver are ok for pilot & clearance, use a small (typical 5V rechargeable) screwdriver for deburring and countersink, and with clutch on lowest or near lowest setting and new quality #2 Philips bits for screwdriving.TL: maybe read anyway!Typically using clamps so drilling multiple holes would align:1. Drill pilot hole(s) through cabinet facing/base material into the trim pieces, to a depth at least the full length of screw, with a 3/32-inch bit. Complete all holes before removing clamps.2. Separate pieces and clean up the holes on the facing surfaces ("touch" holes with 1/4-in cross-hole countersink (c/s) deburring bit).3. On the surface where the screws are inserted, drill through all holes with 1/8-inch bit for clearance.4. On the plywood or hardwood surface where the screw will be inserted:—with plywood deburr if needed (explained in 5 below)—with hardwood, use the same cross-hole c/s bit to create full c/s (go deep enough the whole bit cone portion is completely flush with wood)5. Using a small 5V-type rechargeable screwdriver with a new Philips #2 bit and the clutch set on LOWEST setting*, use firm pressure and drive all the screws in until the clutch rattles. If any screws not fully set, increase clutch setting a click and try again. In plywood, the head will pull in flush or below without prior c/s.I used about 60 screws for this project, and for some parts repeated installation and removal was required. In all only 5–7 screws were tossed after this repeated use rounded the heads, most often as I didn't get a square shot because of awkward locations, and in one case the pilot wasn't drilled deep enough. I never snapped any, or rounded one out enough to require vice grips, using this approach. Where they are visible (black ones into black aluminum supports), they look great.

Trustpilot

1 month ago

2 months ago