Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🖨️ Flex Your Creativity with Precision & Power!

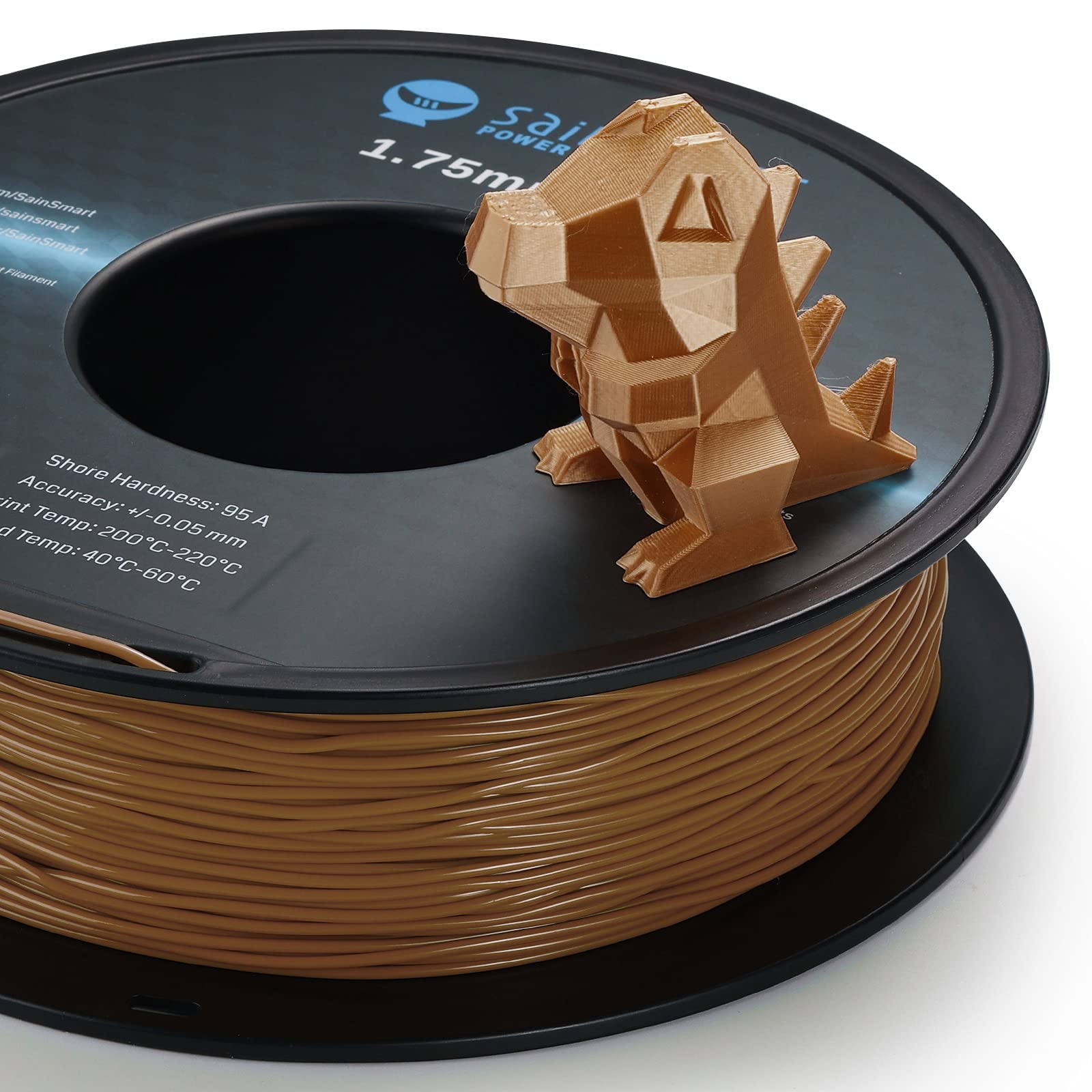

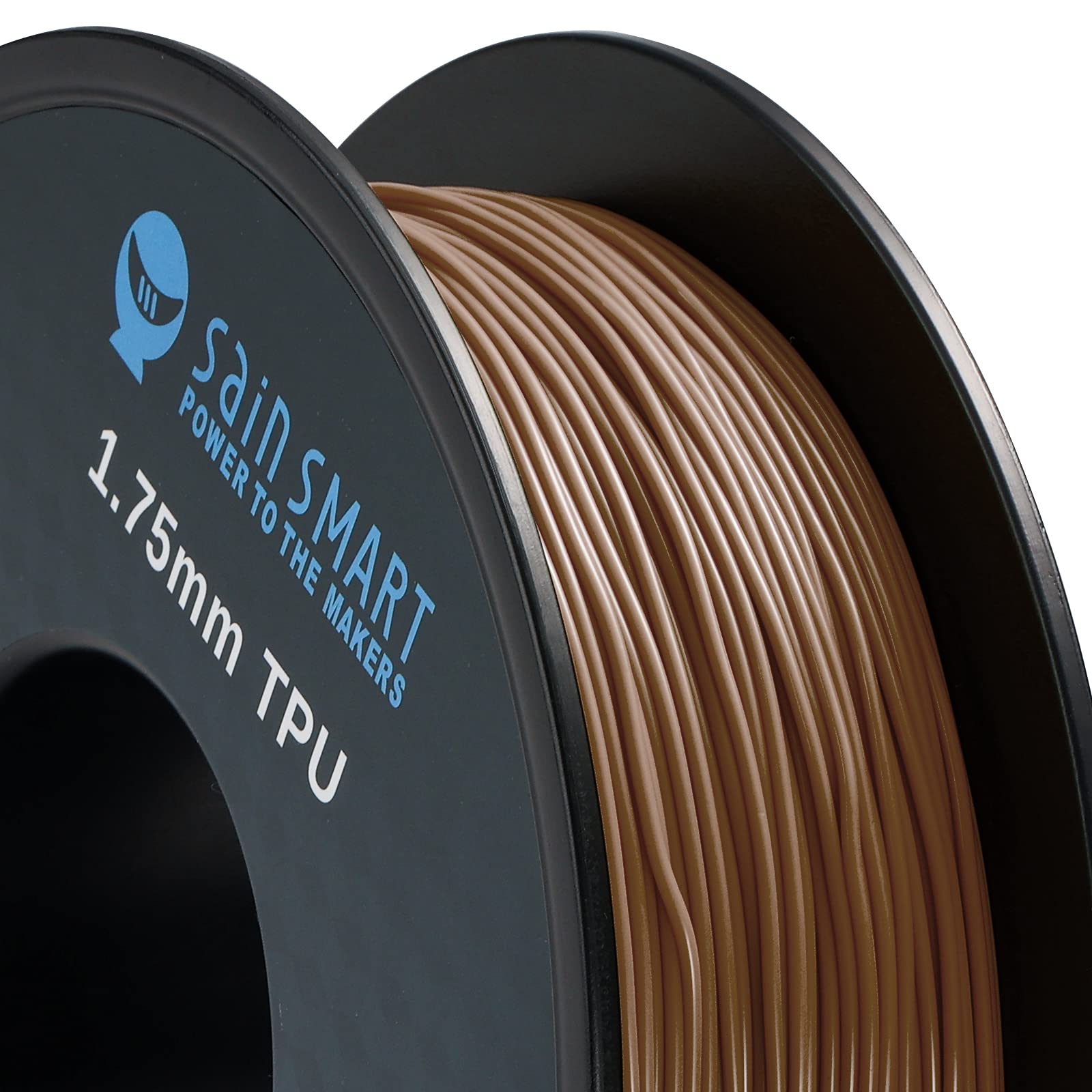

SainSmart Caramel Flexible TPU filament offers professional-grade 3D printing with ±0.05mm dimensional accuracy and Shore Hardness 95A for durable yet flexible parts. Compatible with most 1.75mm printers, this 0.8kg vacuum-sealed spool ensures fresh, reliable prints at recommended temperatures of 195-230°C extruder and 40-60°C bed, perfect for creating resilient phone cases, toys, and more.

S**P

Prints great with a bowden extruder (slowly)

This stuff's pretty awesome. It prints well at 10mm/s through my (long) bowden extruder. Just make sure the area after the filament leaves the extruder gear is closely constrained so there's no gap for the flexy filament to buckle and push out when it's trying to feed.- 10mm/s- 220C- retraction disabled- cooling fan on after first layerI got the TPU in "clear", but it prints kinda milky. Colorwise, it almost looks foamy, but the surfaces are nice and smooth. In my experience it doesn't bridge very well and it can string, but neither is terrible. I recommend picking up some flush cutters to trim the strings; the prints are very durable, and so are the strings! You probably won't be able to cleanly pull them off and sometimes even a razor is tricky to use for cleanup.Layer adhesion is fantastic. Thin-walled prints stretch and squish pretty easily and return to their shape. I haven't seen any delamination yet.A single layer printed on the bed is floppy and droopy like wet paper. Two or three layers are about the stiffness of thick paper. Half a centimeter thick with 25% infill and it's a little less stiff than a rubber spatula. Add thickness and infill and the print starts to feel like a rubber doorstop.TPU is great for printing parts that need to friction-fit together since you don't have to worry about getting tolerances really close. Things will just flex into place.

D**K

Easy-Peasey

Sainsmart has been my go-to for 95a TPU for a few years. Never a problem, and very little stringing. I(f I do a long print, say 20 hours or more, I usually will dry it first just to be safe. Very easy to print. I'm using two Prusa printers, and their Sainsmart profile is perfect.

B**9

I love this stuff (way more than expensive Ninja)

I bought this in black and yellow, waiting on the multi-color pack to get back in stock now. I spent a week in hell, as I was new to FLEX and had to learn some things the hard way. Punch line: this is AWESOME filament! The yellow looks like a glowing fiber optic when light is nearby, it is simply marvelous!! They are both extremely strong, but also soft and lustrous. Super elastic. You can take the single skirt extrusion and stretch it to perhaps 10 times it's size without breaking, but the material seems to remain slightly stretched if you do that, perhaps 30-60%, but after that it always snaps back to that size. Ordinary prints are super strong and hold their shape perfectly.Here are the bottom line lessons learned if you are new to TPU: LOOSEN THE IDLER!; start at 15-20mm/s for everything except travel; be certain your 1st layer is dialed in well for this filament; and TURN OFF RETRACTION. TPU will wrap itself around your extruder gear, or jam, and speed and retraction are the enemy here. Get it to print, enjoy how amazing it is and be happy, and optimize from there!I have a Prusa i3 MK3. My original hell began on this, and I naively tried to use the stock profile for Sainsmart TPU (I mean, it was there, right?). It seemed to work, but ended up dying mid print, almost always. Ended up wrapped around the extruder gear. Annoying to open things up and unravel it. Rinse and repeat, no joy. Played with very many settings, read very many blogs. Nothing worked.Finally blew the dust off my MK3S upgrade kit, bit the bullet, and spent a bunch of hours tearing down and rebuilding my extruder. Tried again, this time switching to the much more expensive *good filament* I bought (Ninjatek). IT JAMMED AGAIN. WORSE. OVER AND OVER. Finally, it basically tied a knot around the gear and I had to do a 50% disassembly of the extruder to get it out (luckily the MK3S upgrade anticipates this and it's easy).Ditched the Ninjatek (I really dislike that filament, it's expensive, has a dull luster, is too soft, and even harder to print, what a bunch of overhype!). Read a bunch more blogs, and finally realized the only real problem was trying to use the stock profile. The answer was go extreme at first, and optimize after you are happy and can go from there. Here are the full changes I made to the stock Sainsmart profile to start with:- Everybody says "loosen the idler"....but to what?! I had to loosen the idler almost entirely, for me almost the entire screw head was jutting out, and perhaps 1-2 turns of the screw were in the nut. This is super important, and I found you can find the sweet spot by starting loosest (screw just biting), try to load, and tighten until it loads, then stop! Experiment from there.- Bed Temp 70 deg C- Extruder Temp 235 deg C- All print speeds 15mm/s (keeping fast travel speed seemed fine, if a little stringy)- Turned off "keep fan always on"- Enabled auto cooling- Turned off retraction! (in Prusaslic3r this is in the printer settings tab under Extruder 1)I have so far turned the speed up to 35mm/s for infill and it seems to work fine, others say 40mm/s works.I love this filament. After a week of misery, once tuned in it just works every time, good luck!

B**N

Yummy In My Tummy

Sainsmart has hands down the best tpu. It prints well, doesn't string as long as you dry it, and is incredibly tough. The translucent filaments are great color matches for kustom canz candy paint (specifically translucent red/ruby red and translucent blue/blueberry). I use it in all my combat robots as armor and for any parts that will take repeated impacts. My only complaint is that the spool is 800 grams instead of the standard 1kg, which is kind of misleading, makes it a worse value than other TPU vendors and unsuitable for larger prints.

J**T

Great Semiflex!

This filament prints great in both direct drive (prusamk3) and bowden (Ender3). Ive printed about 5 or 6 rolls of the black with consistent results. BUT.... make sure the filament is dry. If it's wet, it will print bumpy and look like it's bubbling out of your nozzle. Even new sealed bags can have this problem. So I generally just dry it by default and the keep in a bag with LOTS of silica gel. I use an old food dehydrator at 122F (50C) for about 5 hours or more. I use a separate temperature controller to keep it at the temperature I set. That's important because higher temperatures can cause issues. Some dehydrators get way too hot. Keep this filament dry and you will be happy! Use glue stick on PEI to prevent it sticking too well.This is NOT super soft and squishy. It is called Semiflex. So keep that in mind. I use it for parts that need to be super flexible and durable. Parts printed with this are almost indestructible. You can't tear them or crack them.This is a good choice for your first flexible filament in most printers. 230C to 240C nozzle temps work well. Start at 230C and adjust as needed for good layer adhesion.

Trustpilot

1 month ago

3 weeks ago