Deliver to Portugal

IFor best experience Get the App

⚡ Power your craft anywhere with precision and ease!

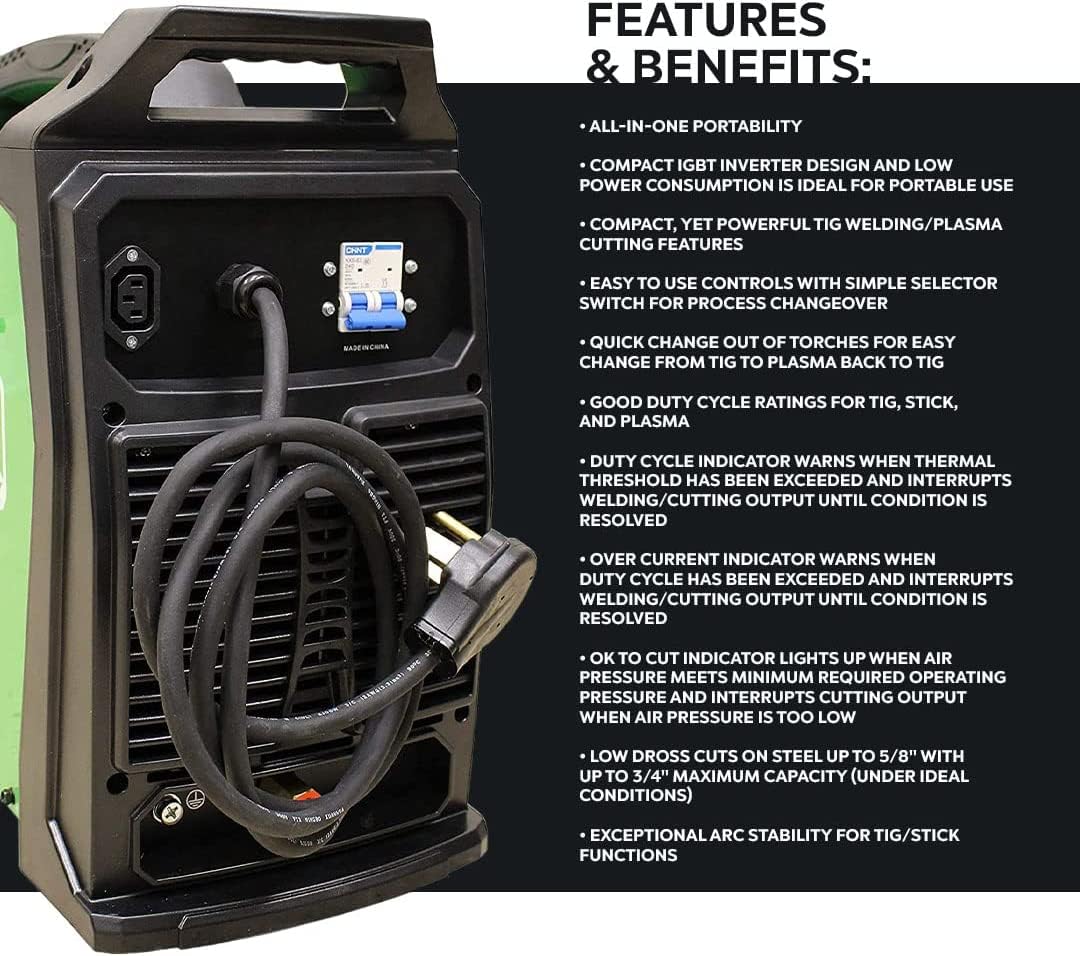

The Everlast PowerPro 205Si is a compact, 200A multi-process welder combining AC/DC TIG, Stick welding, and a 50A plasma cutter. Engineered with advanced IGBT Infineon inverter technology, it offers efficient, reliable performance and low dross cutting up to 5/8" steel. Lightweight and portable at 60 lbs, it’s perfect for mobile professionals seeking versatile, safe, and precise welding solutions.

| Manufacturer | Everlast Power Equipment |

| Part Number | PowerPro205Si |

| Item Weight | 60 pounds |

| Product Dimensions | 22 x 9 x 17 inches |

| Country of Origin | China |

| Item model number | PowerPro205Si |

| Is Discontinued By Manufacturer | No |

| Color | Green |

| Material | Stainless Steel |

| Power Source | ac |

| Voltage | 240 Volts |

| Amperage Capacity | 200 Amps |

| Item Package Quantity | 1 |

| Included Components | Comes as a Combo Set |

| Batteries Included? | No |

| Batteries Required? | No |

C**E

Great service!

This welder combo machine is great! It had some damage during shipping but Jesse and Mark at Everlast Service dept were outstanding to deal with. They identified the damaged part and shipped it out quickly. The welder is easy to use and even a novice can learn and grow up on this machine. The plasma cutter is super handy too.

M**E

VERY IMPRESSED!

I little about my background. I was an owner operator of a metal fab shop from my mid-20s to early 50s. Certified and on approved vendor lists for McDonald Douglas, Hughes Helicopter, General dynamics, plus a few more. My expertise was TIg welding but well versed in MIG, stick, oxy/acetylene. Certifications included Tig welding aluminum, stainless, and a few exotic metals. My go-to machine manufacturer was Miller and I had many of the blue machines over the years. The inverter technology was not around until recent years.I moved on to working in the Oil & Gas industry until my recent retirement and I’m now 70.Recently I wanted to put together a small shop in my garage but didn't have the power requirements available to support an old Miller 250 Syncrowave I had. I found the Everlast unit and impressed with the size, weight, and capabilities, so I bought one. WOW, very stable arc, high freq works great, I got a job welding 3/8 coupler nuts in the end of a 3/4 dia tube, 2000 pieces. Dialed in the pulse and ramps, ended up welding over 500 pieces and still had a fairly sharp tungsten. Great TIG welder and worked well with the air-cooled torch it came with.I also tried out the plasma cutter and stick welding, both worked as expected. Great compact, versatile units for home workshops. I've only had it for a little over a month so cannot speak for its ruggedness or longevity.Was hoping to keep this short but wanted those reading this to decide on a purchase to know a little about my experience.

B**L

I am very pleased with this welder

I am very pleased with this welder. I have not tig welded in over 20 years. Very easy to setup and user friendly. So far I am very happy with this welder and it performs the way it should.

J**S

Flexible multi-application welder and plasma cutter

Just starting to use and learn about the functions... so far pretty good!

P**D

Awesome

It is very good piece of equipment for the price

J**E

Disappointing thus far - air leaks. Update: Set aside leaks and system works good

Four compressed air leaks. Even though a pressure regulator was installed at input of OEM regulator to limit input pressure to 90psi; prior to ever connecting unit to compressed air.One leak resolved by tightening plumbers clamp to point it felt like it was going to snap. OEM clear Plastic air hose seems to be problem, swelling to much for barb fitting.Two leaks required replacing clear/white (silicon) OEM o-rings with black rubber o-rings. The OEM o-rings are to flimsy. Connections were not over tightened. Started off with hand tightening both output connector and plug of OEM regulator, move to snugging them with a wrench, and finally tightening with wrench. Both connector and plug continued to leak, eventually blowing one of OEM o-rings out.Fourth air leak, being most serious, is inside unit. You can hear air leak hissing near front Pressure gauge of unit. Severely leaking to point pressure drops down from 75psi to 72psi. Does not matter if unit is powered on or off.Have not even tried to test Argon line for leaks.**IMO: Gas input lines (Argon & Compressed Air) need to be redesigned. Unit needs to come with two-stage pressure regulator for compressed Air. Since maximum input pressure to entire unit is 90psi, and OEM regulator is for adjusting plasma air cutting pressure up to 85psi. Only way to ensure air pressure never exceeds 90psi with changes to pressure resulting from not cutting, cutting, not cutting.Given strong emphasis Everlast puts on Compressed Air being "dry", unit needs to come with descant cartridge air drying filter that goes before regulator(s). Nearly impossible to find decent air dryer. Tried hardware stores, paint stores, welding stores, and one of big name suppliers.In regards to swapping Argon hose and Air hose going into unit, Everlast needs to come up with something simpler. Suggest either two inputs and internal solenoid valves. Or a kit which has a "T" valve (Left for Argon / Middle Off / Right for Air) with a mounting bracket, and required fittings.**UPDATE: Finally tried TIG. Plastic hose that is factory crimped on to Slip to Flare brass connector leaked. Had to use ratcheting PEX crimper to crimp factory band to stop leaking. Other end needed crimping too. Once done, PP205Si did TIG.Concern is clear plastic tubing is likely to start leaking again because hose swells a lot when pressurized. Can for see issues with hoses aging and the swelling.Update: Raising to three stars, because unit has stayed working. Would have raised to four stars but another hose leak developed. Everlast plastic hosing is weak point of system. Plasma torch coupled to 3rd party drag style tip cuts good.

A**.

Almost do everything

This welder pretty much does everything a small fabricator would need from a welder and plasma cutter. There is a small tradeoff for having such a compact unit. You need to switch some of the cables when going from cutting to welding but that is a small price to pay for the small footprint and portability. The welding and cutting are both very smooth and precise. I highly recommend that you ensure your air is clean and dry for cutting. It will make your cuts better and will make your consumables last longer too.

G**S

Cut AND Weld

I’m not sure what kind of magic they have inside of this box. It has a whole bunch of power to cut and weld. Plasma cutting is sweet and the tig welder is sweeter. I have to admit that I had not stick welded for a few years but it sure seems a lot easier with this welder.

Trustpilot

2 months ago

2 weeks ago